LabLynx KB:SysAdmin - 5.4 LIMS system setup

|

|

This is an article specific to the Category:LabLynx knowledge base. Its context outside of LabLynx, Inc may not be apparent, thus why it appears inside the LabLynx KB namespace. |

LIMS system setup

The testing that a laboratory performs is highly dependent on the workflow, standard operating procedures, and business practices that are adhered to. Because of this, LabLynx designed the LIMS test set-up area to be highly configurable in order to meet the requirements of small, medium, and large laboratory facilities. This document continues to discuss setup of the LIMS system, addressing the concepts of the test parameter and the QC test.

Test parameter

A test parameter is an entity that may require user supplied or system calculated results entry. Commonly, a parameter is a data capturing object required for reporting purposes. Additionally, a parameter can be used to collect information that is required by laboratory management for documentation purposes, etc.

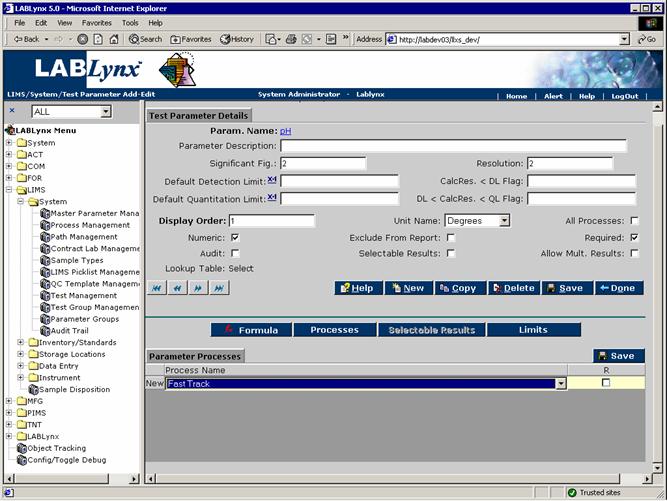

Once the general information for the test parameter is initially defined and saved, the system will allow the user to define the process(es) that the parameter will display. This functionality allows the system user responsible for the test set-up to assign as many pertinent parameters as they require while at the same time giving the flexibility to define at which process(es) the parameter will be displayed. By doing so, this avoids potential confusion of process-specific system users by only displaying a finite list to them and not parameters that they are not required to enter data for.

Once the parameter is assigned to one or many processes from the test path, the system will default that parameter as being required for each process. The user responsible for the test set-up will have the option of de-selecting the Required flag. By doing so, the system will display the parameter to the user at the specific process, but it will not require a value to be entered for it. Conversely, if the Required flag is left checked, the system will mandate that a result be entered for it at that respective process in the test path.

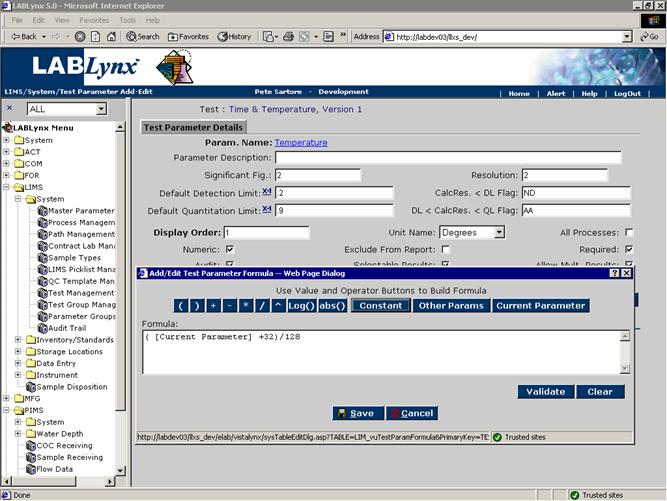

In addition to defining a specific processes for the parameter, a formula may also be defined for results entered during actual test processing once the user has completed the initial save of the general parameter information.

The formula defined for a parameter may reference any of several variables: the raw result of the current parameter, the calculated (prior to rounding) result for parameters of the current test, or another test. An important point must be understood and that is that the system will look for the calculated results for each test parameter that is required in order to calculate the current result from the current sample and not beyond:

Should the parameter not be flagged for all processes, the user will be required to define what processes (from the list of processes in the assigned test path) the parameter is to be displayed in. The user always has the option to show the parameter in all of the processes, a combination of processes, or a single process. For each assigned process, there is a flag that may be checked indicating that the result for the parameter must be entered at the specific process:

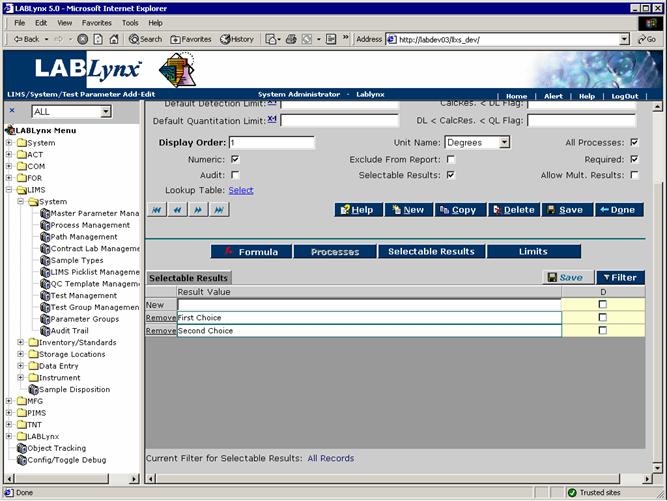

The next action that is available to the user is for selectable results. Should the Selectable Results flag be checked for the parameter, the user may click on the respective button in order to create a predefined list of values for the final result. This allows the user responsible for entering sample test parameter results to simply select from the predefined list in order to reduce data entry, especially when the same results are used over and over again. Once a selectable result is defined, the user may select the check box next to the value they wish to be the default value. This simply triggers the system to display that value for the test parameter result for all samples and not require a change to be made unless required by the data entry user:

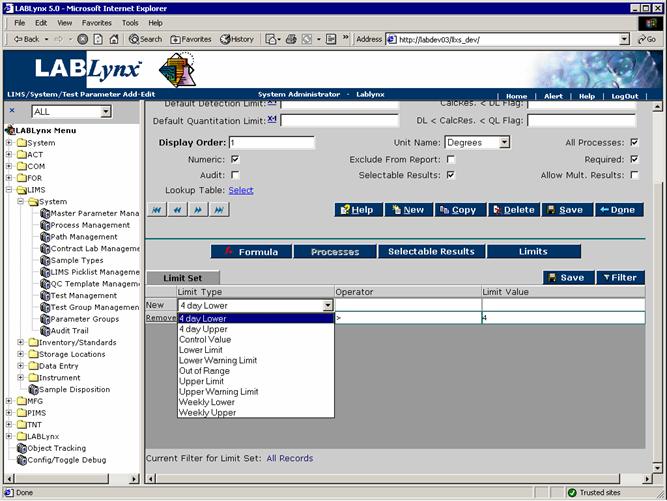

The final option available to the set-up user is for the definition of test parameter limits. The user may select the limits button and see the current list of applicable limits for the parameter. During the initial definition of the parameter, the user may define "n" number of actual limit values. Once the test is published, the system locks down that set of limits (and also the detection limits). The user may also create a new set of limits "n" number of times for the test parameter; each discrete set of limits is given an identifier which is used by the system during actual test assignment to a sample. The unique limit set identifier is always maintained and preserved by the system even as new limit sets are defined. This way past results that were entered into the system can always be related to the applicable limit set regardless of newer limits having been defined.

The user may choose any number of limit types from the picklist and assign them to the respective parameter. Once the type of limit is assigned, the user may then choose an operator (examples would be "<", "<=", "=>", ">", etc.) from a LabLynx level user-defined picklist. Upon selection of an operator the user may then assign the actual numeric value for the limit type and operator. The system assumes the limit value to be in the units of measure as that of its respective parameter:

Example: A user wishes to define the upper and lower calibrated limits for the instrument used for the alkalinity test.

- Once the user has assigned the Alkalinity parameter to the test, he or she selects Upper Cal. Limit from the picklist and assigns the operator of "<=" and finally the value of "100."

- The user next selects Lower Cal. Limit from the picklist and assigns the operator of "=>" and defines that value as "0."

- The system will, during the entry of results for the Alkalinity parameter, check to see if any limits have been defined, which in this case they have, and will compare the user-entered result value against any and all limits associated with the test parameter. In this example the system would compare the result to the two limits values and validate the result.

- If the user enters "34mg/l" the system compares the "34" value to make sure it is less than or equal to "100" for the upper ca. limit and again checks to make sure that it is greater than or equal to the "0" lower cal. limit. In this case the user would not be alerted to any limit violations because the entered value is within both defined limits.

During the set-up of the test and its parameters, there is no limit to the number of limit assignments that may be made to the parameter. The system will simply continue to run through the list of assigned limits for the parameter and alert the user to any limit definition that has been exceeded.

QC test

Quality control (QC) tests are based on previously created tests in the system. They may be created by one of two means. The first of which is through the use of a QC template. Using a QC template allows the use of a predefined template and allow the system to auto-generate a QC test based on the parameters in both the QC template and the actual test. The second method available for use in the creation of QC tests is on an ad-hoc basis.

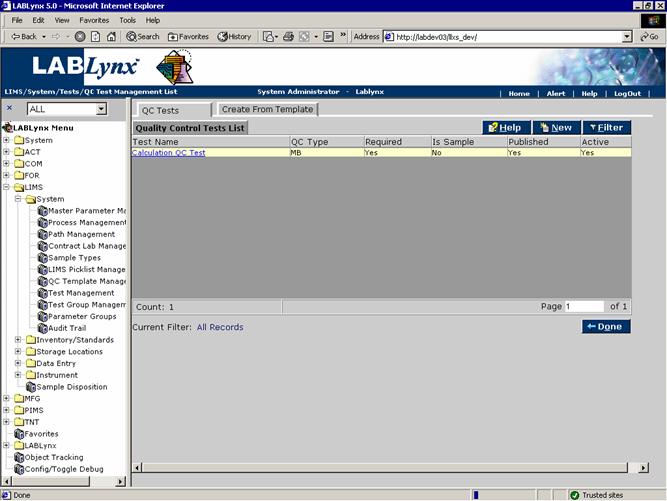

The user sees a list of the QC tests that are set up for this test. From this screen the user may also create a new QC test by clicking on the New button:

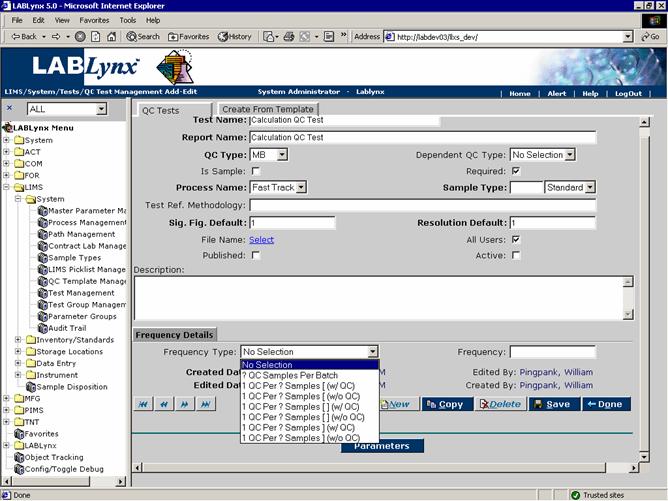

The user then sees the information for the QC test. This screen is very similar to that of the test details screen. One major difference is the ability to define the frequency in which a QC test will be assigned. The user can define how often a QC test is to be run per the user-defined number of samples for a given test:

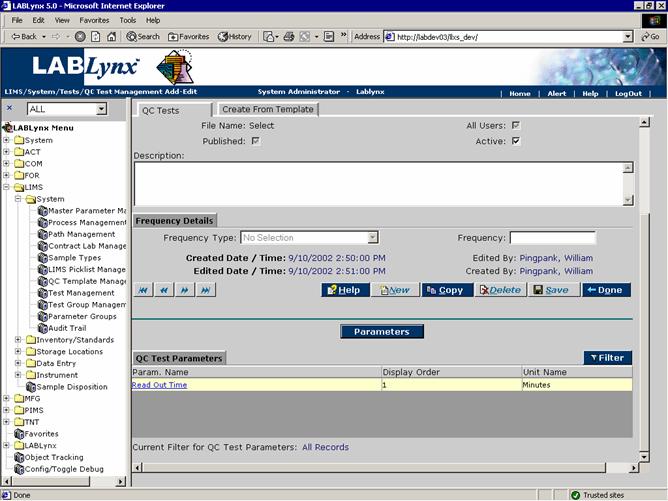

Once the QC test has been defined and saved, the user may then add/edit the associated parameters. In the case where the user has opted to create the QC test using a predefined QC template, the system will have already have created the associated parameters, and the user may simply validate the information. Alternatively, if the QC test has been created ad-hoc, the user will be required to define the parameters and their associated data:

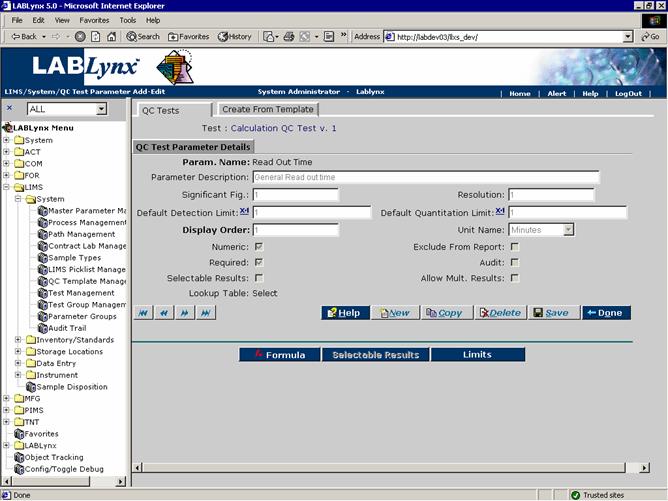

Once the general information for the QC test parameter is initially defined and saved, the system operates under the assumption that the QC test parameter will appear in all test path processes (defined at the parent test level) from the QC test process creation point on forward.

In addition to defining specific processes for the parameter, once the user has completed the initial save of the general parameter information, a formula may also be defined for results entered during actual test processing. The tools available to the user for building the formula are standard arithmetic (addition, subtraction, multiplication, division) as well as log base 10, exponent, and absolute value:

The limit information for the QC test parameter follows the same logic as that of the standard test parameter defined earlier. In summary, a user may assign "n" number of limit values to the parameter for validation and comparison at the time of results entry.